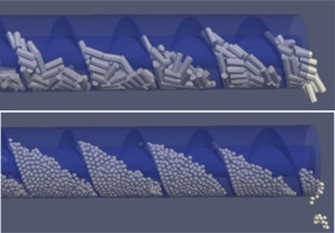

Screw feeders are extensively used in agriculture and processing industries to transport bulk material at relatively controlled rate. The flow behavior can be affected by present moisture content as well as by shape and size of particles which tend to cause bridging or arching of material. In this work, the cohesion between mono-sized spherical particles (due to moisture content), is simulated parametrically by means of cohesion energy density parameter. The correlation acts as an additional normal force to Hertz elastic theory to maintain the contact between two particles. Further, the work is extended by comparing the flow behavior of spherical with non-spherical particles by introducing the non-sphericity (cylindrical shape) using superquadric approach. The superquadric DEM simulation has shown good agreement with our experimental studies for model validation. The simulations quantify the screw feeder performance in terms of average particle speeds (radial, swirl and axial) and contact forces (normal and tangential) by varying screw rotational speed, flight pitch ratio and particle feedrate. The average radial and swirl speeds have shown opposite variation for bigger particle size with increasing cohesion energy density for all three varying conditions. The contact forces between particles also increases with increasing cohesion energy density. The quantitative results depict the same behavior for non-spherical particles as for spherical particles, but with lower magnitude for average particle speed as well as for contact forces.

DOI: https://doi.org/10.1016/j.powtec.2021.117049